How Does a 4-Wire Sensor Cable Work?

How Does a 4-Wire Sensor Cable Work?

When you buy a 4-wire sensor cable, you will have several options. These options include Normally-closed, Normally-open, and Number of pins. Fortunately, the manufacturers of these cables will indicate the wire colors corresponding to the input and output functions of their sensors.

Normally-closed

A Normally-closed 4-wire sensor cable consists of two pairs of wires for power and data. The power wire goes to the panel’s ECP bus, and the data wire goes to the sensor’s zone terminals. This type of sensor cable is the most commonly used. It is typically marked -A in Pepperl+Fuchs order. It is typically used with motion sensors.

Normally-closed sensors send power to a PLC only if an object is detected. A normally-open sensor doesn’t pass power to the PLC until an object is detected. Many sensors available from AutomationDirect come with normally-closed outputs. This type of sensor cable manufacturers eliminates the need for rewiring, but it is more expensive than axial cable.

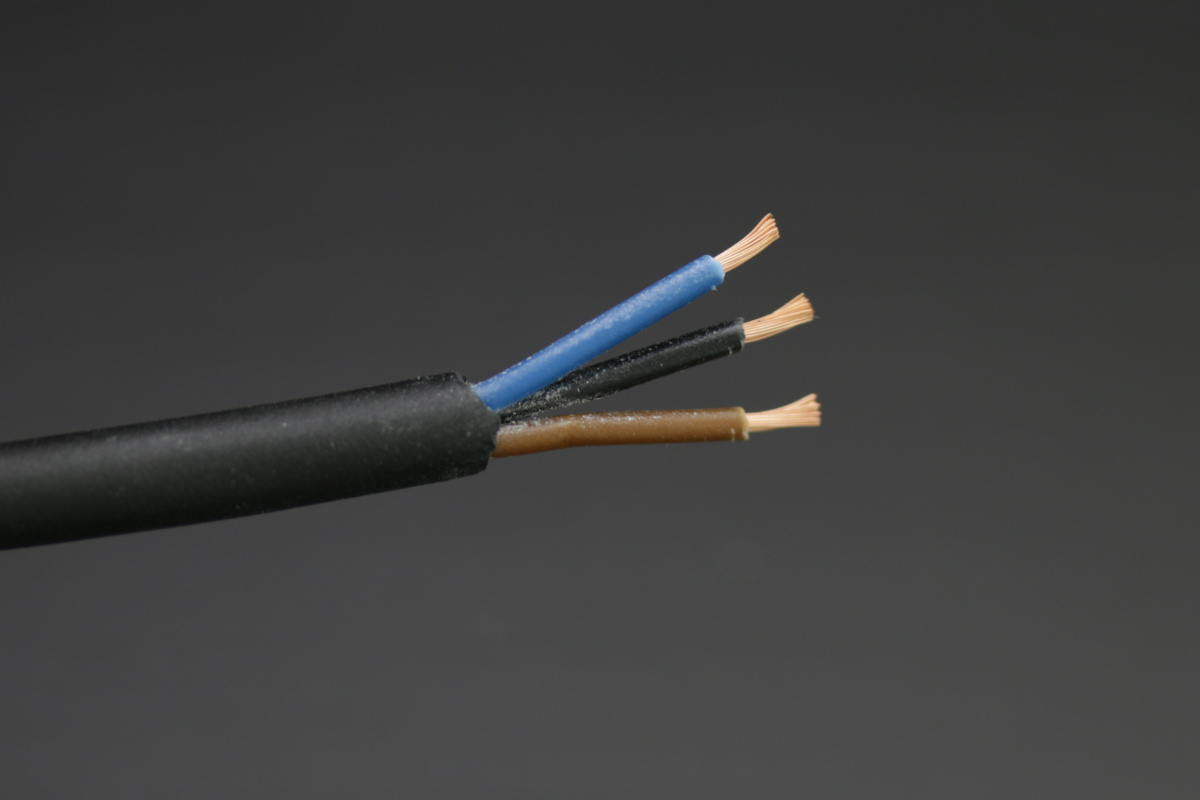

NC and NO sensors are similar except for their contacts. In both types of sensors, the power supply terminals are connected to the positive and negative terminals. The first signal output at terminal 2 is positive for PNP sensors, while the second signal output is negative for NPN sensors. If you’re trying to determine which type of sensor you have, you can measure the voltage between the black and blue wires to determine whether the signal is negative or positive.

The distance between the two sensor wires must be at least twice as wide to ensure optimal sensing accuracy. Normally-closed 4-wire sensor cable can be used in a variety of applications. For example, a switch can be used to detect a change in temperature or voltage, so it’s important to consider the distance of the target.

The most common cause of erratic electrical operation is poor grounding. The problem occurs when a ground is shorted to a metal part or buried inside a metal conduit. In some cases, the grounding point is hidden, covered in grime. Before you start any work on your car, you should check the harness diagram to determine where the ground is located. If the grounding points are hidden, you should try to touch them with your fingers. Another way to check the sensor cable for ground is to make a test lead. A crocodile clip or a spring hook is ideal for making a good test lead. This lead should be long enough to reach the sensor ground wire.

A voltmeter can also help you find the problem. You can use it to measure the resistance of the sensor cable wire by connecting it to the battery and the black ground cable. A resistance reading of more than 0.2 volts means that a sensor cable has a resistance problem.

Sense wires

When measuring resistance, a 4-wire sensor cable is the most accurate way to measure it. This cable uses a two-wire connection, a pair of force and sense wires, and a third pair of extension wires. Depending on the application, the sensor cable may have a different gauge.

When using a sensor cable, be sure to consider the number of pins in the sensor and the wires in the cable. The Source pin can carry up to 1A, which requires a 22-gauge wire. On the other hand, the Sense pin carries almost no current, so it may be a bit thinner. If the cable needs to be flexible, consider using polyethylene or TPE material.

Typically, a four-wire sensor cable will have two outputs – one active and one inactive. Both can be evaluated simultaneously for diagnostic purposes. The two signals also assume the same state in the event of a lead breakage, short circuit, or power failure. This increases signal safety and plant availability.

In addition, four-wire sensor cables are easy to calibrate. Just be sure to follow manufacturer’s instructions. If you are installing your sensor cable, ensure that you use the right connectors and do not shorten or cut the cable. This will ensure accurate measurements every time. And when it comes to connecting two sensors, make sure to keep the wires from getting crossed and causing problems.

A four-wire sensor cable is very accurate and can be used to test any electrical device. In addition, the four-wire connection is ideal because it has separate wires for current measurement and voltage sense. In the real world, this type of connection is not perfect and varying resistances can affect the result.

If you are not sure if your 4-wire sensor cable is functioning properly, you can connect a voltmeter to check the voltage. You can install a voltmeter between the black and blue wires, and between the white and brown wires. After checking the voltage, you can install your sensor.

Using a multimeter to test the sensor’s electrical connection is another option to identify the sensor type. The multimeter should measure the voltage between the 0V wire and the black wire. A voltage of +24V indicates a PNP sensor, while a negative reading means an NPN sensor.

Number of pins

When choosing a sensor cable, it’s important to consider the number of pins. Four-wire sensors, for example, typically have four individual pins. You must match the number of pins on the cable to the number of pins on the sensor. The pins are located at the opposite ends of the sensor, so you should be able to match them.

You can also check the voltage of the sensor by using a digital volt ohm meter. The voltage should be either 12VDC or 24VDC depending on the sensor. If the sensor doesn’t display a voltage, the controller is not powering the sensor correctly. If the sensor isn’t receiving voltage, remove the connector and plug it into another device. You should also check the continuity of all the wires in the speed sensor’s wiring.

Another way to test the sensor’s connection is to test the lambda sensor. It’s important to use a high-quality digital volt ohm meter to measure the resistance in the cables to the heating element. When testing, make sure to use an accurate ohm meter and test probes. Ensure that the cable is properly secured, and that the resistance is between two and fourteen ohms. Also, make sure the cable is greased with the supplied grease. Be careful not to use grease that contains lead or metal based additives.

Temperature sensors such as the DS18B20 work with a proprietary one-wire protocol that allows them to communicate with one another. This is similar to I2C, but instead of using separate data and clock lines, a single line is used. A one-wire temperature sensor can be interfaced with an Arduino library.