Advantages of Medium Voltage Motors

Medium Voltage Motors

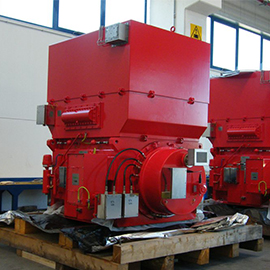

Electric motors are found in most of the world’s industries, powering everything from pumps, blowers and fans to conveyor belts, paper mills, crushers and shredders. They are also used to operate industrial machinery in hazardous environments where dust, vapors and ignitable flyings can create dangerous conditions. For these applications, motors with a medium voltage (MV) rating are often the best choice, as they offer greater safety and protection for workers and equipment than low voltage (LV) versions do.

While the exact definition of medium voltage motors varies by industry, most agree that it refers to AC induction motors operating at voltages of 6kV and higher. The term is based on the voltage range needed to achieve the required torque for a given load, and the higher the voltage, the more current the motor will require to operate at full speed.

Depending on their use, MV motors may need to be run at very high speeds for extended periods of time. This requires an insulated stator that will not conduct heat to the steel frame and other components, so manufacturers typically use a form wound insulation system and vacuum pressure impregnated (VPI) process. These systems also protect the windings from contamination by air flow and help prevent short circuits.

Advantages of Medium Voltage Motors

To reduce current and torque surges, MV motors also are designed to operate with reduced voltage during startup. This reduces starting current and enables the inrush to be limited during start-up, and a contactor or bypass switch is used to short out the reduced-voltage devices once the motor has reached full speed. Typically, the reduced-voltage starter is combined with an inverter drive, which converts DC voltage stored in the DC bus into a variable frequency alternating current waveform to control the motor’s speed.

Another advantage of MV motors is that they can be operated in most standard industrial facilities. This is because LV motors typically need large copper conductors to carry the required amps, and this can require extensive cable runs across a plant. In contrast, MV motors allow for the same performance in a smaller wire gauge, which reduces cost and limits power losses over long distances, according to Mr. Polcyn of GE Industrial Systems.

The size of a MV motor also makes it less susceptible to damage from sudden overloads and short-circuit power surges. This is because MV drives have built-in protection and fault monitoring features to avoid over-voltages and other damaging events. Other advantages of MV drives include harmonic cancellation and active front-end control, which further improve energy efficiency and reliability over time. Lastly, MV drives can be mounted outside of buildings without needing an additional enclosure or power distribution gear, which is especially beneficial in areas with tight floor space.